Home >> Machinery >> Food Processing Machinery >> Water Bottling Machine >> Details

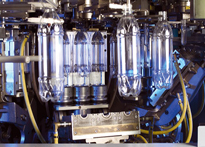

Blow Moulding Machine

Blow moulding machine, blow moulding machien for buckets, bottles, tanks, liquid containers.[08-12-25 16:02:30]

|

Our blow moulding machine is specially designed for the production of buckets, bottles, tanks, containers and other containing tanks. The capability can be adjusted as well as the raw material. The whole moulding machine included: feed head, extrusion system, clamping device, blowing device, hydraulic system, controlling system...

All data below are only based on our previous successful projects and are only for your reference, we can adjust the specification according to your requirements. |

|

MODE: Series of HFBC752(single station, Double head ,max product volume 5L)

The blow molding machine mode HFBC752 is specially designed for producing 1-5 gallon buckets, and it can also be used for producing other kinds of bottles, lampshade etc.

OUTPUT for 5 Gallon bucket: 1 bottle/70sec.

Blow moulding machine |

BASIC INSTALLATION INCLUDING

Head: center-feeding head Extrusion system: Adopt transducer and speed reducer motor to control screw rotate speed. Clamping device: Adopt bi-directional synchronous clamping device with four axis single cylinder. Blowing device: Blowing device with upper blowing type Hydraulic system: The whole hydraulic system adopts controlling components with famous brand and proportional controlling circle. Electric controlling system: Adopt PLC made in Japan and touch screen is imported. Every electric component is in famous brand. |

ORIGIN PARTS OF HFBC752, Blowing moulding machine

|

PLC/PLC |

FP2National FP2 (made in Japan) |

|

Transducer |

ATV28/58TE(Made in France) |

|

Temp. controller |

OMRON |

|

Relay |

OMRON |

|

Stretch switch |

Using electric rule |

|

Motor |

Beide China |

|

Oil bump |

Yuken |

|

Hydraulic valve |

REXROTH |

|

Pipe connecting part |

Korean |

|

Hydraulic hose |

Import from Occident |

|

Sealing |

Imported |

|

Hydraulic accessories |

Imported |

|

Pneumatic valve |

FESTO |

Blow Moulding Machine,Blow Moulding Machine,Blow Moulding Machine,Blow Moulding Machine,Blow Moulding Machine,Blow Moulding

Inclosure: Technical data and parts instructions of blow molding machine for series of HFBC752,blow moulding machine

1. Max. article volume (L) :5(double head); 12(single head)

2. Extrusion system of blow moulding machine:

2.1 Main extrusion system of blow moulding machine

Diameter of screw: 75mm

Length/diameter ratio of screw: L/D=25/1

Screw rotation rate( rev. / min. ): 10~80

Plasticizing efficiency: HDPE: 90kg/hr

Heating zone: 3

Heating power(KW):12

Motor power(KW):30

2.2 Auxiliary extrusion system of blow moulding machine

Diameter of screw: 25mm

Length/diameter ratio of screw: L/D=25/1

Screw rotation rate( rev. / min. ): 10~60

Plasticizing efficiency: HDPE: 5kg/hr

Heating power(KW):1.5

Motor power(KW):2.1

3.Die head system of blow moulding machine

Mode of general constructions: continously extruding as per the principle of “ first in and first out”. Single head, double heads, three heads, four heads, double layers head, visible stripe head, accumulator head, uniform parison surface, easy to exchange color and material.

Mode of heating: adopt heater band made of stainless steel

Temperature controlling: Adopt automatic temperature controllers such as OMRON

Heating power:10KW

Zones of heating: 3

Center distance:250mm

Material of die head: nitride, boride or chromizing imported rustproof steel

Max. Diameter of head: 150mm

4.Clamping device of blow moulding machine:

Mode: Clamping system designed by the patent. Adopt bi-directional synchronous clamping device with single four-axis cylinder. Declining-move basement makes it easy to cut parison with little impact and uniform motions.

Clamping force: 125KN

Distance between platens: 200~560 (mm)

Thickness range of mold: 100~260 (mm)

Size for mold platens: 500 X 400

Max. Dimension of mold: Width ×Height 520mm×400mm

5.Blowing system of blow moulding machine

You can select to install single blow pin, double blow pins, three blow pins, four blow pins, hydraulic balance blowing system and triple-direction moving device. The moving down speed of blow pin, with the function of rotating and inching, is adjustable easily.

6.Hydraulic system of blow moulding machine

Big pump rated pressure( MPa ):5

Small pump rated pressure( MPa ):10

Big pump rated flux( L / min. ):94

Small pump rated flux( L / min. ):28

Motor power(KW):15

7.Pneumatic system of blow moulding machine

Air source pressure( MPa ):0.7

Work pressure( MPa ):0.6

Air consumption( M3 / min. ):0.4

8.Water:

Pressure( MPa ):0.3

Flux(m3 /min ):0.4

9.Electric source :

Voltage: AC 380V/50HZ

Mode of wire: three phase, four lines

Voltage range: ±10%

General rated power(KW):65

Average energy consumption ( KW h ):35

10. Overall dimensions of blow moulding machine:

Length×Width×Height 3.5m×2.2m×2.8m

Weight: 6 T

Finished production of series of HFBC752,blow moulding machine

1. Max. article volume (L) :5(double head); 12(single head)

2. Extrusion system of blow moulding machine:

2.1 Main extrusion system of blow moulding machine

Diameter of screw: 75mm

Length/diameter ratio of screw: L/D=25/1

Screw rotation rate( rev. / min. ): 10~80

Plasticizing efficiency: HDPE: 90kg/hr

Heating zone: 3

Heating power(KW):12

Motor power(KW):30

2.2 Auxiliary extrusion system of blow moulding machine

Diameter of screw: 25mm

Length/diameter ratio of screw: L/D=25/1

Screw rotation rate( rev. / min. ): 10~60

Plasticizing efficiency: HDPE: 5kg/hr

Heating power(KW):1.5

Motor power(KW):2.1

3.Die head system of blow moulding machine

Mode of general constructions: continously extruding as per the principle of “ first in and first out”. Single head, double heads, three heads, four heads, double layers head, visible stripe head, accumulator head, uniform parison surface, easy to exchange color and material.

Mode of heating: adopt heater band made of stainless steel

Temperature controlling: Adopt automatic temperature controllers such as OMRON

Heating power:10KW

Zones of heating: 3

Center distance:250mm

Material of die head: nitride, boride or chromizing imported rustproof steel

Max. Diameter of head: 150mm

4.Clamping device of blow moulding machine:

Mode: Clamping system designed by the patent. Adopt bi-directional synchronous clamping device with single four-axis cylinder. Declining-move basement makes it easy to cut parison with little impact and uniform motions.

Clamping force: 125KN

Distance between platens: 200~560 (mm)

Thickness range of mold: 100~260 (mm)

Size for mold platens: 500 X 400

Max. Dimension of mold: Width ×Height 520mm×400mm

5.Blowing system of blow moulding machine

You can select to install single blow pin, double blow pins, three blow pins, four blow pins, hydraulic balance blowing system and triple-direction moving device. The moving down speed of blow pin, with the function of rotating and inching, is adjustable easily.

6.Hydraulic system of blow moulding machine

Big pump rated pressure( MPa ):5

Small pump rated pressure( MPa ):10

Big pump rated flux( L / min. ):94

Small pump rated flux( L / min. ):28

Motor power(KW):15

7.Pneumatic system of blow moulding machine

Air source pressure( MPa ):0.7

Work pressure( MPa ):0.6

Air consumption( M3 / min. ):0.4

8.Water:

Pressure( MPa ):0.3

Flux(m3 /min ):0.4

9.Electric source :

Voltage: AC 380V/50HZ

Mode of wire: three phase, four lines

Voltage range: ±10%

General rated power(KW):65

Average energy consumption ( KW h ):35

10. Overall dimensions of blow moulding machine:

Length×Width×Height 3.5m×2.2m×2.8m

Weight: 6 T

Finished production of series of HFBC752,blow moulding machine

After saling blow moulding machine, if necessary, We will send one or two engineers to set up and commissioning of the blow moulding machine until it running in normal state. Druing the time your workers who will operate the blow moulding machine will be trained.

Chinese

Chinese English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian