Home >> Machinery >> Paper & Pulp Industry Machinery >> Tissue Packaging Machine >> Details

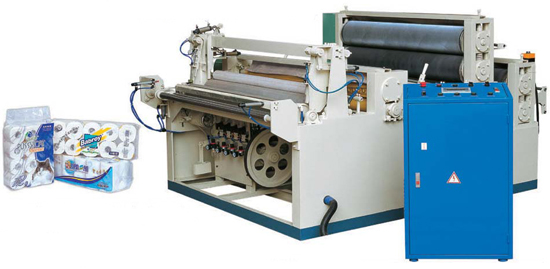

Perfoarting Rewinder

Perfoarting Rewinder,Perfoarting Rewinder,Perfoarting Rewinder,Perfoarting Rewinder,Perfoarting Rewinder,Perfoarting Rewinder,Perfoarting Rewinder,Perfoarting Rewinder,Perfoarting Rewinder,Perfoarting Rewinder,Perfoarting Rewinder,Perfoarting [09-01-19 22:48:16]

This machine adopts the advanced technology of PLC computer programming, variable frequency speed regulating, electronical brake and HMI operation interface. The machine has won state patent for its excellent practice of all device equipped on the machine, and has got reputation from its users since pushing to the market. It is your ideal choice for producing hight-quality toilet/kitchen paper roller, for it can reduce consumption and increase economic benefits.

1. Paper unwind stand vertical style and horizontal style

1)Features of vertical paper unwind stand:

Pneumatic paper loading, deliver paper with pneumatic wide belt, with seperate tension control device for each roll of raw paper, raw paper are lay in friangle-shaped. It has the advantage of loading paper more easily and quickly than horizontal style.

2)Features of horizontal paper unwind stand:

Pneumatic paper loading, original paper line-placed, deliver paper with pneumatic wide belt, with seperate tension control device in each roll of raw paper.

2.The paper unwind stand can be equipped with web-edge controlling function which controlled by PLC. This function is effected by an electric eye to inspect and trace the web edge, then the electric eye will transfer the data to the web-edge controlling performer to effect the aim of alignment of different paper webs. With the web-edge controlling function, the web edge of different paper web will be kept parallel with each other even if the paper roll is transferring in high speed, thus can reduce waste of paper roll edge.

3. Equipped with warming device for indicating adding paper tube or stainless steel.

4. Function of automatic stop at the broken of paper can be added.

5. The rewinding technology of this machine is the first invention in China. It can make the finished paper reel tightly first and the loosely, it can give the different elasticity for different parts of paper roll, especially, paper core won't seperate from paper roll after a long time of store(controlled by micro-computer).

6. Automatic changing paper tube and unloading finished product. The paper tube or stainless steel tube can be adjusted from diameter 25mm to 50mm random in 1 min, rewinding in high speed.

7. Comparing to those papers from single embossing, the paper with double embossing and edge-gluing is softer, the embossing effect in both layers of the finished products will be complete the same, more over, each layer doesn't scatter when used, and the paper roll in same size is 15% lighter or above. It is especially fit for processing kitchen roll.

8. The synchronized finished of automatic edge-cutting, gluing and tail-sealing can reduce consumption of paper when the roller paper are sent to the process of slitting by circular saw and packing. The working efficiency and the paper grade can be greatly increase as a result. With paper ending left, it is convenient to use.

9. The machine can be equipped with tail trademark embossing device at position of 4cm away from th tail, this will make paper tail of three layers won't scatter, and can prevent the product from imitation. It's especially fit for producing of paper roll without embossing.

10. Gluing compounding device proceed kitchen paper roll with large diameter gluing roller and computer to control the quantity of glue.

11.The adopting of up-guided method to wind finished paper, and the frontand back instant button switch to guide original paper, make the operation much simpler.

Automatic edge-trimming, sealing and perforating rewinder

The development of automatic edge-trimming, sealing and perforating rewinder based on the function of rewinder. It integrate the developmental demand of customers, operating simply and easily, having high efficiency for the production. It is an ideal equipment for the production of toilet tissue.

Fully-automatic embossing perforating rewinder

This machine adopts the technology of PLC programming, variable frequency speed regulating and HMI operation interface. This machine itegrates the functions of embossing, punching, automatic paper tube changing and auto-matic sealing in one. It can greatly increase the production efficiency and guarantee good quality of fraping roll with the non-stop continuous work of auto-paper core changing. The automatic sealing can reduce wastage, and is convenient for slitting. The adopting of spiral soft blade in punching, enable the machine to be operated with low noise, and clear slitting with slight pull, and the length and weight is adjustable according to the requirement. And also, the machine utilizes air pressure adjustment to adjust the elasticty of rewinding papers roll, especially suit for the processing of coreless paper roll, mid-grade and low-grade toilet paper roll.

Jumbo roll tissue perforating slitting/rewinding machine

Jumbo roll tissue perforating slitting/rewinding machine has the features of double functions of producing small jumbo roll and tiolet roll rewinding and slit at the sme time, pneumatic paper loading rewinding by air-shaft and with embossing and with embossing and polishing device, etc.

Point to point embossing perforating rewinder

Point to point paper embossing rewinding and perforating machine can transfer the jumbo paper roll into embossing roller by back rack's belt, the paper embossed double sides pictures by two set embossing devices, and perforated, rolled into slick size, the double sides embossing devices make the paper more loose and no small hole, the pneumatic original paper rack can make original paper up and down automatic, it has the advantages of lower noise level and distant embossed patterns, each piece of sheet can be seperated by a gentle pull.

ZQ-III paper embossing, rewinding and perforating machine

ZQ-III paper embossing, rewinding and perforating machine is to rewind and perforate the big paper rolls according to needs, the machine uses spiral brade for dotted lines stamping. It has the advantages of little wearing rate, low noise level and distinct embossed patterns, each piece of finished paper can be separated adjust by a gentle pull, the tightness and sheet size and weight can be adjustable.

ZQ-SY Jumbo paper roll color printing rewinding machine

ZQ-SY jumbo paper roll color printing rewinding machine. The paper can be ink printed with colorful pictures by the printing device of this machine and rolling into big-axle-paper. It will be used with square-packing machine or cut into paper roll for napkin machine.

After saling Perfoarting Rewinder, if necessary, We will send one or two engineers to set up and commissioning of the Perfoarting Rewinder until it running in normal state. Druing the time your workers who will operate the Perfoarting Rewinder will be trained.

Chinese

Chinese English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian