Home >> Machinery >> Light Industy Machinery >> EVA Slipper Machine >> Details

Proposal for EVA Slipper Machine

EVA Slipper Machine, EVA Slipper Machine, EVA Slipper Machine, EVA Slipper Machines, EVA Slipper Machines, EVA Slipper Machine, EVA Slipper Machinery, EVA moulding machine, EVA Slipper Making Machines, EVA Injection Moulding Machine[09-01-07 23:13:29]

|

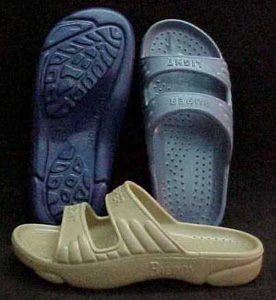

The eva slipper machine is suitable for producing eva foamed and moulded multi-color slipper. The whole production line includes material feeding system, mould closing system, PLC control system, hydraulic system. It's quite an ideal choice in the shoe making industry.

The data below are based on our previous projects and are only for your reference, we can adjust the specification according to your requirements. |

|

Main Technical Data of Automatic of EVA slipper moulding machine

|

Model |

HDE-203Z |

HDE-206Z |

HDE-210Z |

|

work stations(NO.) |

6 |

6 |

6 |

|

clamp force(T) |

170 |

170 |

170 |

|

heating Plate Size(mm) |

500*290 |

500*290 |

500*290 |

|

heating plate power(kw) |

36 |

72 |

120 |

|

max mould-opening stroke(mm) |

350 |

350 |

350 |

|

heating mode |

electric heating |

electric heating |

electric heating |

|

heating plate number(NO.) |

4 |

4 |

4 |

|

injector number(NO.) |

2 |

2 |

2 |

|

injection capacity (max.)(cm3) |

928 |

928 |

928 |

|

diameter of screw(mm) |

60 |

60 |

60 |

|

rotating speed of screw(r.p.m) |

0~150 |

0~150 |

0~150 |

|

injection pressure(pa) |

900 |

900 |

900 |

|

total power(kw) |

126 |

162 |

210 |

Main Specification of EVA foam injection moulding machine:

1.Adopting proportion pressure valve and speed control valve to precision control injection quantity & pressure, ensure lasting produce high quality products.

2.Vertical pressure cramp mould unit have high cramp force, able to autocontrol cramp mould unit size change cause of thickness, temperature.

3.Per station have 2 moulds, per mould can standalone forcing, height of hold mould can auto control by the mould height, so it suit for all kinds of mould. Pressurize kong able pressure distribute more uniformly for the big size mould, thus increase the mould operating life and products unease appear fash.

4.Increase the heating plate size, Great injecting quantity & exactitude with the injecting material optimize design of an optimized performance, suitable for the production of one-mold multi-pairs.

5.2 zones slow-quick speed open & close mould appear, Large mould-opening stroke, easy for taking out the finished products and cleaning the moulds.

6.Touching-screen control man-machine interface--able to continually check if both functions of diagnosis and service are working normally during work so as to make sure of it, with the data visible to get an easy operation.

7.Quick movement of injector--using a linear slide rail, driving by rack, quick displacement and accurate positioning.

8.Easy to adjust the thickness of mould that no zones adjust from 100-200mm.

9.Adopting servomotor-reducer and closed loop digital control system in slipper making machine.

10.Adopting high precision heavy linear guide rail, shift more accuracy.

11.Adopting physics character superpower oil less bearing.

12.First adopting calculi curve theory control injection capacity and temperature.

13.Adopting the positon transductor which with the highest precision in the market to control matched molds and injection.

14.Adopting the double proportional flow pressure control valve, modular pilot controlled check valve .

16.Huge vacuum & pneumatic system.

16.Huge vacuum & pneumatic system.

15.Adopting new model super low damp oil hydraulic cylinder.

After saling EVA slipper machine, if necessary, We will send one or two engineers to set up and commissioning of the EVA slipper machine until it running in normal state. Druing the time your workers who will operate the EVA slipper machine will be trained.

Chinese

Chinese English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian