Home >> Machinery >> Construction Materials & Equipments >> Concrete Block Making Machine >> Details

Concrete block making machine

Concrete block making machine

Concrete block making machine has wide applications in various field. This type of Concrete block making machine inherits all the merits of the original model, enhanced by new technology. Compared with other Concrete block making machine, our Concrete block making machine enjoys many advantages including: more reasonable structure, more compact appearance, smoother operating, higher efficiency and is easy to operate and maintain. Concrete block making machine has wide adoptablity, is an ideal Concrete block making machine for you to convert into production. Concrete block making machine that you need is just what we can supply. We are one of the most famous Concrete block making machine exporters in China. We have been supplying a whole set of Concrete block making machine for overseas customers. We would like to provide maximun customer satisfaction at lowest possible cost and best after-sale service. If you need Concrete block making machine, please feel free to contact us.

|

|

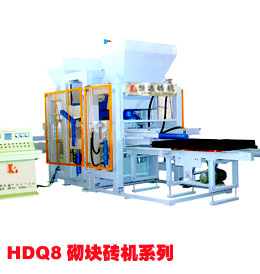

Model HDQ4;HDQ6;HDQ8;HDQ10 bricklaying block shaping machine: |

change mould can produce wall brick、 heat-insulated brick,lawn brick、stack brick、square brick、protect slope、road shoulder、road board、river road etc.The machine has many functions. Shaping period is 10-15 second then it can produce pavement bricks 60m2 or wall bricks 10-15m3. Make the oil that excessed when it was pressured into vibrating power,the computer controlls the vibration、frequency conversion、brake and concel vibration energy consuption. low frequency charging、hing frequency vibration make the concrete liquified、exhaust entirely in 2 or 3 seconds to ensure the product with high density and high intensity.It is especially for compose high intensity hydraulic.It can be stacked when shaped and it reduces the invest. The photoelectricity controlls the storage,and the material gets when need.This avoids the infection of the residual vibration.Part of concrete liquifies ahead of time. Special break arch device,distributing material speedly and equably.A pendular charging device is put inside the hopper.The material is put into the mould equably by adjust the balanced fork. Import electrical equipment、hydraulic organ make the control and hydraulic system run with no problem. Adopt human and machine interface,chinese menu.Modify every parameter at any moment according to the products and the material.Diagnose engine trouble automatically.The control system is intellectualized. Technical data:

![]()

characteristic:

![]()

shaping brick number

390×190×190 6 blocks/mould

240×115×90 15 blocks/mould

shaping period

10-15S

Stimulating force of vibration(can be adjusted)

Ma×90KN

vibration frequency(can be adjusted)

Ma×4300rpm

General power of the while set

36.8KW

outline size

6370mm×2000mm×2510mm

JS500 compelling type two horizontalaxes concrete mixer:

![]()

type

JS500

mix engine power

18.5KW

output capacity

500L

takeup engine power

5.5KW

input capacity

800L

pump power

0.75KW

productivity

20-25m3/h

electric handspike engine power

0.55KW

os material max.diameter

80/60(mm)scree/detritus

outline size(mm)

4450×3005×4610

mix axesrotate speed

35.5rotate/minute

General quality of the while set

4000 KG

![]() apply range:

apply range:

The machine may be used for all middle or small prefabricated parts factory、road、bridge、irrigation works、harbor 、dock and other industry poepole use architecture works.It can mix dry-rigid、plastic、fluid concrete and other pulp.

It has the advantage of reasonable design、close structure、save labour operate、high mix quality、high produce rate、low energy consuption、organ long life and dependable work.

|

|

Lift trigger: |

Get more information about auxiliary equipments for brick making machine, please click there

Get more information about concrete block making machine, please click there

Get more information about excavation equipment, please click there

Get more information about Mixing extruder, please click there

Get more information about brick making machine, please click there

After saling Concrete block making machine, if necessary, We will send one or two engineers to set up and commissioning of the Concrete block making machine until it running in normal state. Druing the time your workers who will operate the Concrete block making machine will be trained.

The pioneers in exporting Concrete block making machine in China.

Chinese

Chinese English

English German

German Spanish

Spanish French

French Italian

Italian Portuguese

Portuguese Japanese

Japanese Korean

Korean Arabic

Arabic Russian

Russian